On April 11, Novatron held a corporate cost analysis training meeting. The purpose of this training was to deeply interpret the core meaning of cost reduction and efficiency improvement, strengthen the cost awareness of all employees, and actively respond to market challenges, thereby enhancing Novatron's core competitiveness.

This training was personally led and explained by Executive Vice President Li Wenxing, and Chairman Qian Yanan was specially invited to attend the meeting.

Under the leadership of Executive Vice President Li Wenxing, all participants stood up and solemnly took an oath.

The resounding oath echoed in the conference room, each word filled with everyone's firm determination and sense of mission towards the work of cost reduction and efficiency improvement.

At the beginning of the training, Li Wenxing first explained the changes in the current macroeconomic environment and the severe challenges faced by enterprises. He stated that cost reduction and efficiency improvement are the only way for enterprises to respond to market challenges and achieve high-quality development.

Executive Vice President Li Wenxing

He emphasized that cost reduction and efficiency improvement must be a systematic process involving all employees and proposed a five-step strategy for enterprise cost reduction and efficiency improvement:

Conduct cost reduction and efficiency improvement workshops to unify employee awareness

Reduce explicit costs but focus on major areas

Reduce implicit costs and stimulate organizational vitality

Find business growth points to achieve efficiency improvement

Continuously optimize internal management to form a virtuous cycle of high-quality development.

In the severe market environment, PLM, TPS, and KPI are of great significance to the operation of enterprises. Since 2024, Novatron has gradually established and improved the operation mechanisms of KPI, PLM, and TPS.

What is their significance in enterprises?

KPI (Key Performance Indicator): Used to measure the key results of an organization or individual in achieving strategic goals, usually represented by quantitative indicators (such as sales, production efficiency, quality pass rate, etc.).

PLM (Product Lifecycle Management): Manages the entire lifecycle data and processes of a product from concept design to retirement, covering R&D, manufacturing, sales, service, and other aspects.

TPS (Toyota Production System): With "Just-In-Time" (JIT) and "Automation" as its core, it achieves efficient production by eliminating waste and continuous improvement, exemplifying lean production.

What is the relationship between them?

KPI is result-oriented: clarifies "what" (such as quality, cost, efficiency).

PLM is the data and process foundation: answers "how" (such as cross-departmental collaboration, data sharing).

TPS is the execution tool: ensures "it gets done" (such as waste elimination, continuous improvement).

How to carry out specific operational processes?

KPI sets the goal

PLM plans the path

TPS executes the optimization

KPI verifies the effect, forming a continuous improvement loop

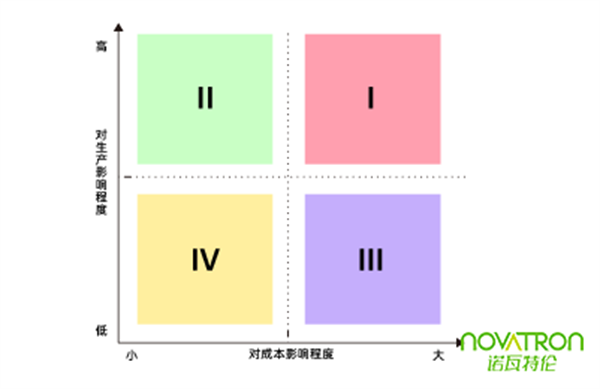

After the interactive exchange session, Li Wenxing shared a working method with us——the Four Quadrants Rule.

He stated that the reasonable use of the "Four Quadrants Rule" can help us scientifically plan our work, focus resources on key areas, thereby significantly improving work efficiency.

The purpose of the Four Quadrants Rule is to help us shift from "busy but ineffective" to "focused and efficient," allowing Novatron to achieve sustainable growth in the uncertainty of market changes.

After clarifying task priorities, the enterprise can concentrate resources to handle high-value tasks, reduce resource waste, and avoid neglecting long-term risks (such as compliance loopholes) due to urgent matters (such as sudden crises), achieving a balance between risk prediction and response.

In the future, Novatron will use this training as an opportunity to further establish and improve a long-term mechanism for cost reduction and efficiency improvement, strengthen monitoring and assessment of the work of various departments, ensure that various measures are implemented, to achieve sustainable development of Novatron, and create a better future.

+86-(0)571-88634319

+86-(0)571-88620157

English

English 中文

中文 日本語

日本語 한국어

한국어 français

français Español

Español italiano

italiano русский

русский português

português العربية

العربية ไทย

ไทย